*** SALES ON SELECTED PRODUCTS UP TO 50% OFF!!! ***

1

/

of

3

PERFORMANCE AT IT'S BEST

High Performance

Tuning with Future

Motorsports

If you are looking for power and performance, look no further. Future Motorsports prides itself on our Tuning & High Performance History. We can help bring out the most from your vehicle. From baseline Dyno Pulls and Dyno tuning to full custom tuning solutions for.

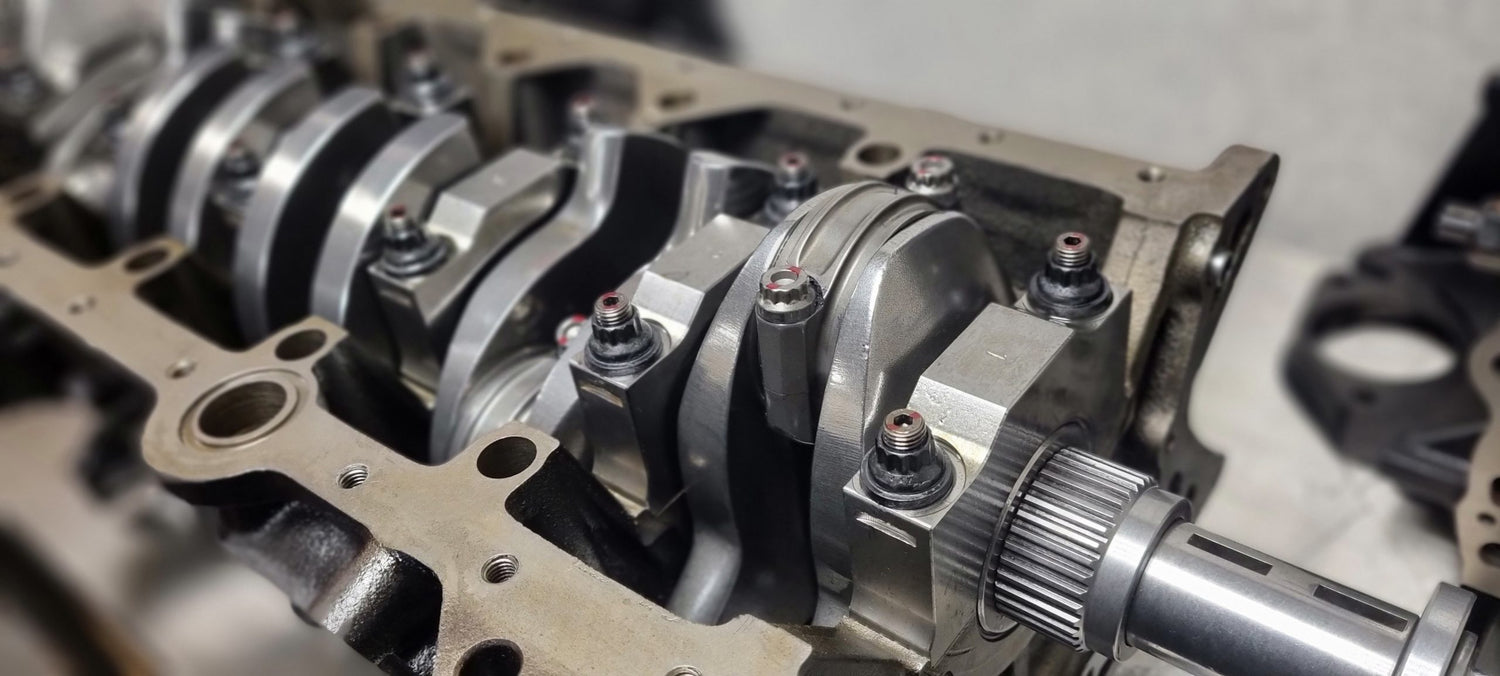

HIGH PERFORMANCE & RACE

ENGINE BUILDING PROGRME

SOPHISTICATED FACILITIES

INCLUDING IN-HOUSE

MOTORSPORT ENGINEERING.

WITH OVER 20 YEARS EXPERIENCE IN THE AFTERMARKET AND RACING INDUSTRY, FUTURE MOTORSPORTS HAS BEEN SYNONYMOUS IN BEING PART OF SOME OF THE FASTEST VEHICLES AND ENGINES IN EUROPE.

PERFORMANCE PARTS SHIPPED WORDPWIDE

WITH COMPETITIVE

INTERNATIONAL AIR

FREIGHT RATES!!!

ABOUT FUTURE MOTORSPORTS

Future Motorsports can mail order & ship your high performance parts anywhere in the world.

We use fast air freight deliveries (even on our large weighted items like built cylinder heads or built short blocks).

Tell your brand's story through images

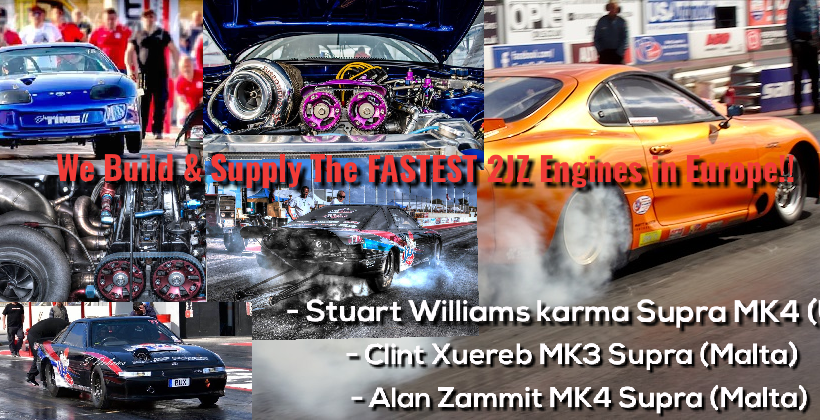

Alan Zammit's MK4 Supra From Malta With a Future Motorsports 2JZ Short Block. Doing 7.8sec Quarter @ 174mph

Clint Xuereb's MK3 Supra From Malta With a Future Motorsports 2JZ Engine. Doing a 7.6sec Quarter @ 174mph,

Future Motorsports is a Technical Partner & Parts Supplier to Stuart Williams's "Karma Supra" making a 7.7sec Quarter @ 178mph pass.

Ryan Toporowski S15 Drift Car with a Future Motorsports 2JZ 3.4ltr Engine.

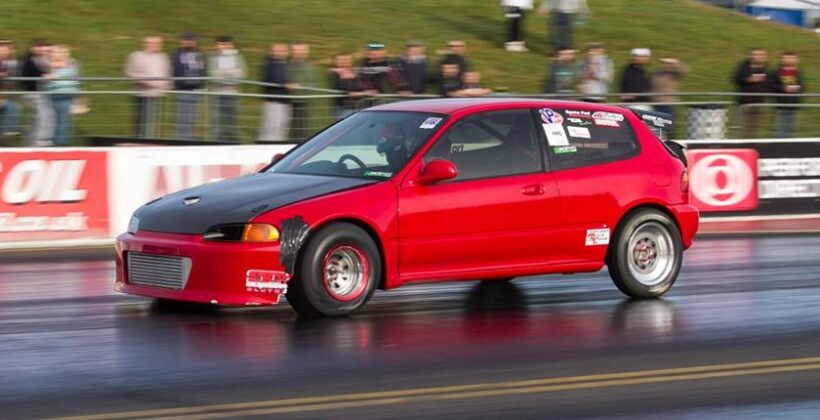

Calvin Skerritt's 9.2sec Quarter Mile @ 163mph Honda Civic Turbo Drag Car. Built & Tuned By Future Motorsport

Jamie Owen's S14A SR20DET Drift Car Mapped By Future Motorsports

Ryan Toporowski S15 Drift Car with a Future Motorsports 2JZ 3.4ltr Engine.

Ryan Toporowski's S15 Drift Car with a Future Motorsports 2JZ 3.4ltr Engine.

Jamie Owen's S14A SR20DET Drift Car Mapped By Future Motorsports

Future Motorsports is now an Official ProEFi Dealer for the UK & Europe. We are able to supply ECU and Tuning Packages. ProEFi is used in some of the most fastest street and race vehicles in the world. Contact us for pricing and options or look in the menu. Many plug and play applications available.

Amy Bradley's 10.3sec Quarter Mile @ 148mph Honda Civic Turbo Drag Car. Built & Tuned By Future Motorsports.